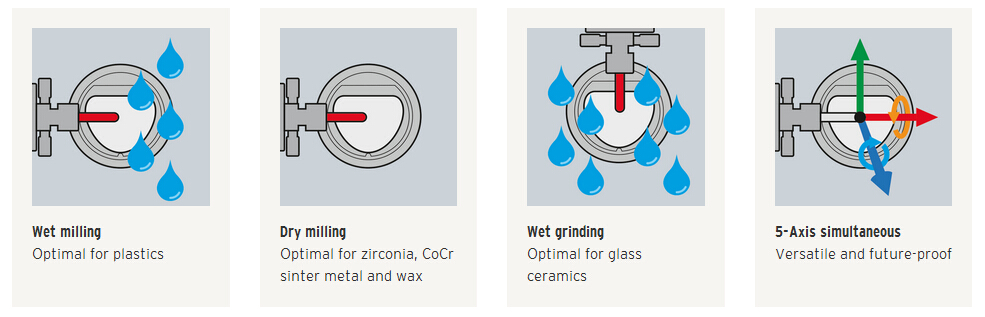

With the Ceramill Motion 2 it will be possible to retain the value creation chain of prosthetic and framework digital fabrication almost entirely inhouse – for any size of laboratory. Ceramill Motion 2 combines the 5-axis milling technique (wet/dry) with the wet-grinding technique in a compact machine. The machine can be used not only as a purely dry or wet system, but can also be operated in the wet and dry combination mode. In the combination mode operation can be easily changed between milling and grinding mode (by exchanging the blank holder).

- -Material-appropriate processing for each material (e.g. zirconia dry, plastics wet)

- -Extremely compact design (small installation space, fits in any type of laboratory)

- -Modular and upgradable with other material blank holders (e.g. for processing glass ceramic)

- -Newly developed “speed boost” milling strategies for maximum productivity

- -Tool holder with automatic tool changer

- -Low maintenance, very precise and extremely robust Jäger spindle

- -Highly efficient blow-out function and tool cooling provided by integrated air nozzles on the spindle as well as a coolant unit in wet operation

- -Automatic tool length measurement and broken tool detection

- -Also ideal for practice laboratories (grinding technique inlays, onlays, etc)

- -Can be used with open CAD/CAM systems (3Shape®, Dental Wings®)* (*after verification using the Ceramill Upload Tool)

- -Dimensions D/W/H: 588 x 516 x 755 mm

- -Weight: 78 kg

- -Electrical connected value: 100-230V 50/60 Hz

- -Electrical fuse: T3,15A / T6,3A

- -Power output: 250 W

- -Motor speed: 60000 rpm

- -Compressed air: 6 bar / 50 L/min.

- -Suction: prepared

- -Wet processing; prepared

- -Torque: 4 Ncm

- -Chuck diameter: 3 mm

- -Noise level: 60 dbA

- -Accuracy: <10 µm

- -Number of axes: 5